About Anti Static Additive Masterbatch

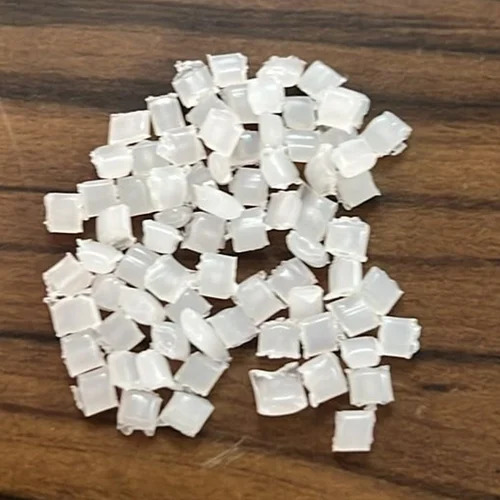

Anti Static Additive Masterbatch is engineered to minimize static electricity buildup, ensuring safe and efficient operation in industrial applications. Crafted from ABS (Acrylonitrile Butadiene Styrene) as its carrier, this highly pure additive with 99% purity is offered in the form of granules. Designed for use in injection molding processes, it enhances the quality and performance of molded products by imparting unique anti-static properties. Its fine-tuned composition provides consistent results, making it ideal for manufacturers requiring reduced electrostatic discharge risks. This products reliability and adaptability cater to various industries seeking optimal material handling and improved safety standards.

FAQs of Anti Static Additive Masterbatch:

Q: What is the primary purpose of Anti Static Additive Masterbatch?

A: It is designed to reduce static electricity buildup in materials, improving safety and performance in industrial applications.

Q: What form does this product come in?

A: Anti Static Additive Masterbatch is provided in granule form for easy integration into manufacturing processes.

Q: Can it be used in injection molding applications?

A: Yes, this masterbatch is specifically formulated for use in injection molding processes.

Q: What material is used as the carrier in this masterbatch?

A: ABS (Acrylonitrile Butadiene Styrene) serves as the carrier for the Anti Static Additive Masterbatch.

Q: How pure is the masterbatch?

A: The product boasts a high purity level of 99%, ensuring consistent performance and quality.